Technology and capabilities

Tailored engineering services

In a state-of-the-art production facility in Bandon, Co. Cork, Reliance manufacture high precision engineering components and sub-assemblies for supply direct to customers or for collaborative projects with the group’s facility in Huddersfield, UK.

High accuracy racks

The site in Ireland was originally established to manufacture high accuracy, ground racks for the machine tool industry, and they are still a core product today. The unique method of grinding the tooth profile has enabled Reliance to become world leading in the production of high accuracy racks.

The Racks are commonly used in medical devices and high accuracy positioning systems. Reliance racks can be manufactured to a pitch accuracy of 0.005 mm over a distance of 300 mm in lengths up to 1 m and are available in a choice of materials.

Leadscrews

Reliance leadscrew and nut assemblies provide a flexible, integrated solution for linear motion. Available in a wide choice of leadscrew sizes and nut styles, they are available in a range of materials and coatings with a choice of standard or custom machined interfaces.

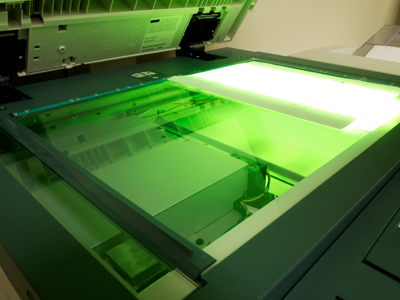

A Vici Vision optical measurement system specifically for high accuracy lead screw measurement has recently been added into production.

Assembly

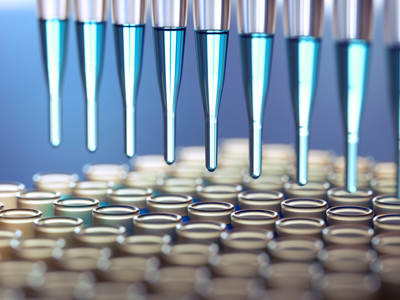

High precision clean components are assembled in Class 100 laminar flow cabinets. These assemblies are supplied to a diverse range of markets including scientific, medical, semiconductor and aerospace industries. A fully qualified ESD assembly area also allows handling of components sensitive to electro-static discharge.

Flexible shaft couplings

Coupling manufacture was introduced to Ireland in 1999 after a phase of development work. Recognising that the performance of a machine is only as good as the connections of its shafts, Reliance’s range of shaft couplings have been carefully designed and tested to provide trouble free operation over many millions of cycles.

The Reli-a-Flex™ range of couplings is an aluminium alloy, one piece configuration, which has been designed in-house to provide very smooth transmission of motion, high torsional stiffness, low bearing loads and long life.

The patented slot pattern was developed after many months of analysis and test. This provided the best balance between zero backlash, torsional stiffness and low bearing load, whilst attaining an operational life in excess of 50,000,000 cycles at rated load and 80% offset. With two sets of identical slots, the Reli-a-Flex™ coupling is a constant velocity by design, and handles angular, parallel and axial offset.

Ceramic grinding

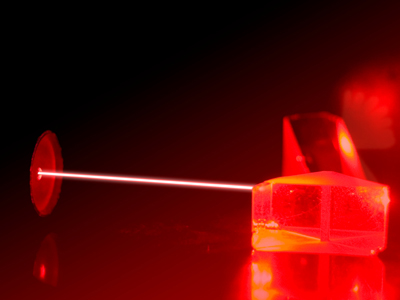

Ireland has been responsible for Reliance’s ceramic grinding process since 2001, using jig boring machines in a controlled environment to machine ceramic components to an accuracy of 0.002 mm. The precision components are then assembled into a quadrupole mass filters.

These are used in the mass spectrometry industry, an area of technology in which Reliance is now regarded as a world leader.

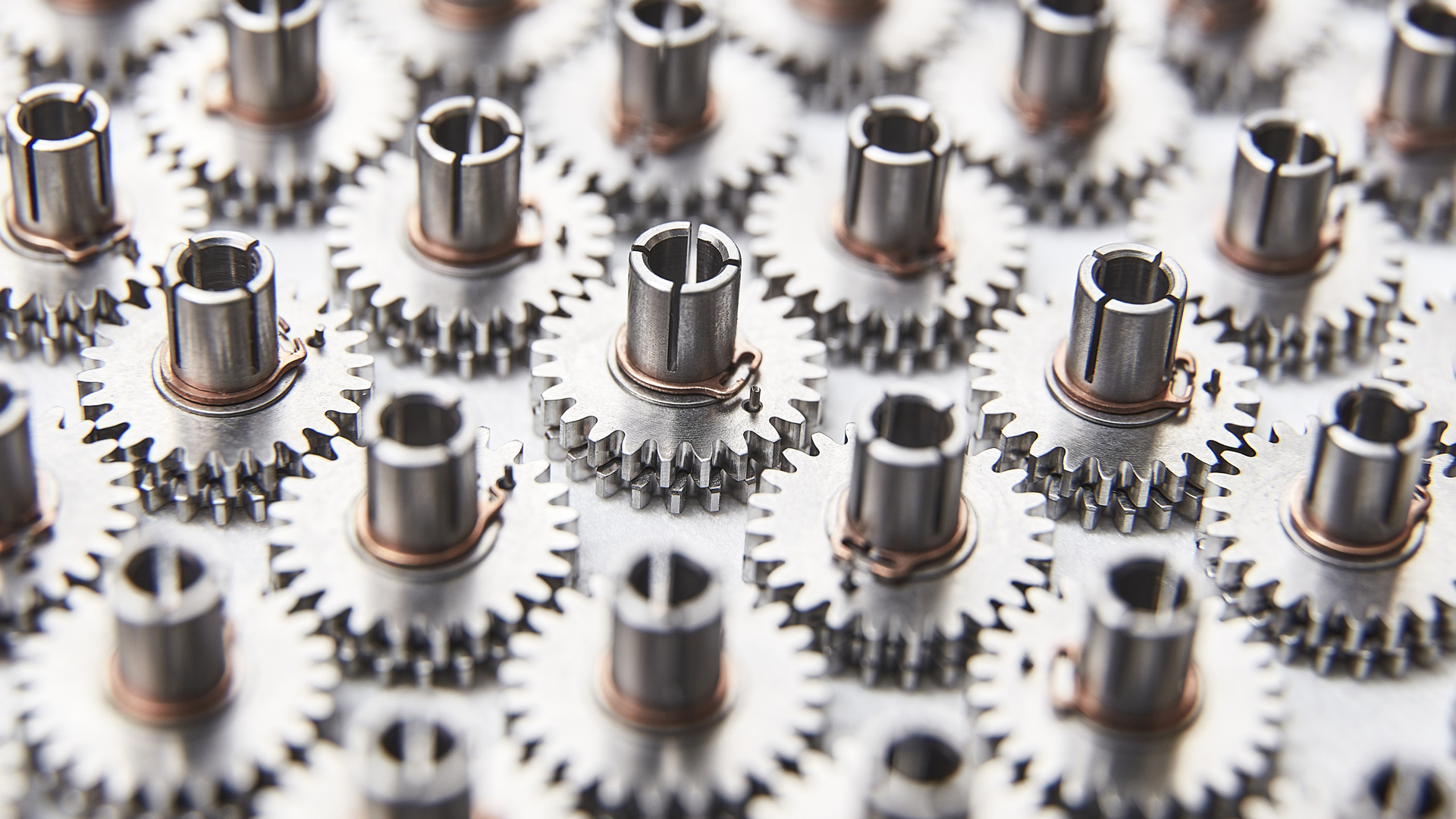

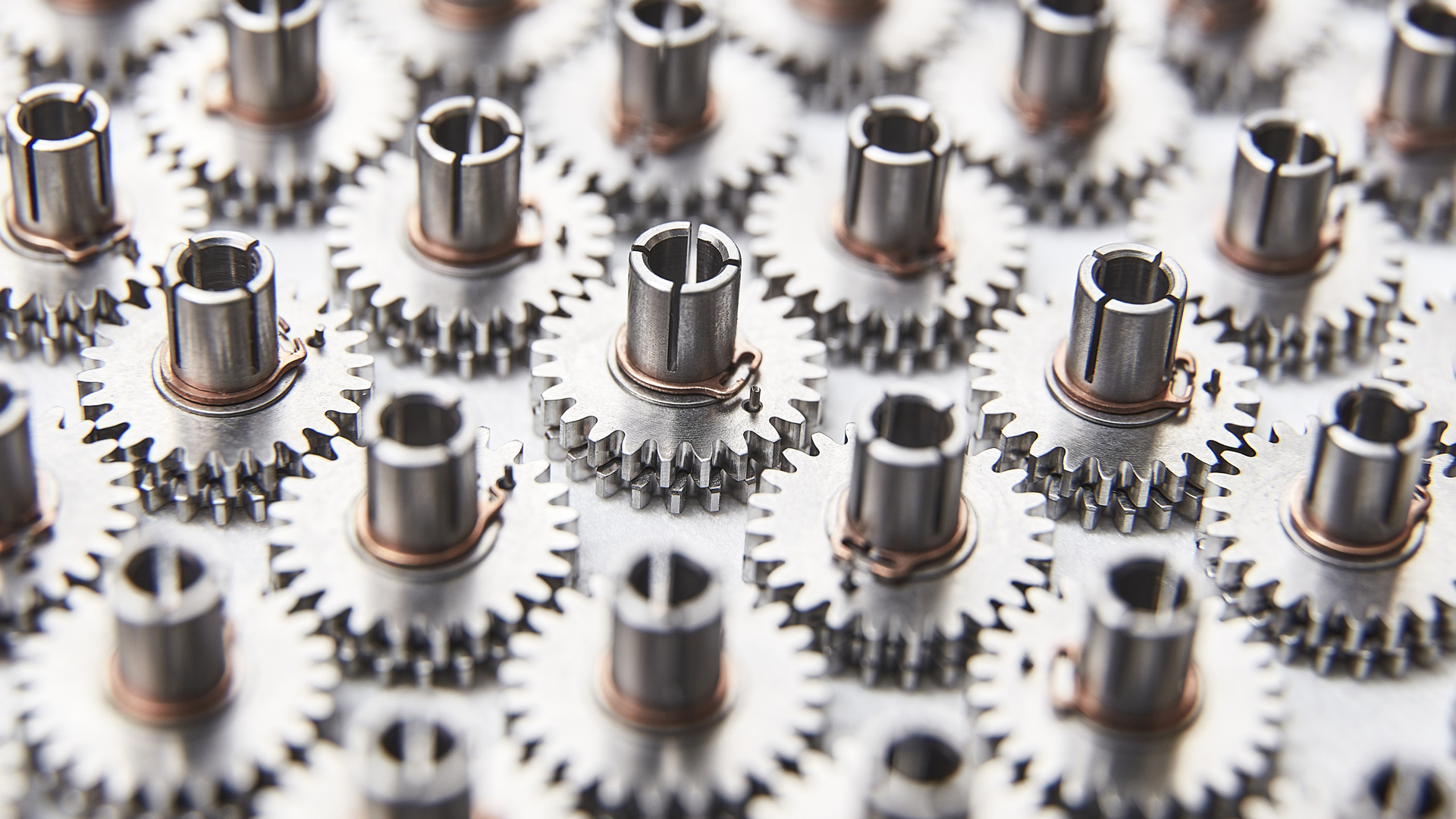

Precision anti-backlash and standard gears

With over 50 years of experience in the design and manufacture of precision spur gears, Reliance has developed an extensive range to suit a wide variety of customer applications.

Reliance offers a wide selection of anti-backlash gears, spur gears, hubless gears and hardened gears with many hundreds of thousands of combinations of bore size, face width, material, module, and number of teeth.

Recently, Reliance have successfully concluded a phase of testing and development on a new CNC gear hobbing machine with automation for component loading and unloading. The addition of this machine further strengthens Reliance’s capabilities. This helps to increase productivity of standard gears with highly precise, highly accurate results.

It has also allowed the introduction of worm and worm wheel production.

Standard products

Ireland is home to Reliance’s Standard Products business and responsible for the supply of all catalogue products. These include products from essentials such as captive screws to complete sub-assemblies for rotary and linear motion and control.

Reliance also offer an integrated solutions assembly for more complex assembly or sub-systems comprised of standard, modified and bespoke elements.

Technology and capabilities

Tailored engineering services

In a state-of-the-art production facility in Bandon, Co. Cork, Reliance manufacture high precision engineering components and sub-assemblies for supply direct to customers or for collaborative projects with the Group’s facility in Huddersfield, UK.

High accuracy racks

The site in Ireland was originally established to manufacture high accuracy, ground racks for the machine tool industry, and they are still a core product today. The unique method of grinding the tooth profile has enabled Reliance to become world leading in the production of high accuracy racks.

The Racks are commonly used in medical devices and high accuracy positioning systems. Reliance racks can be manufactured to a pitch accuracy of 0.005 mm over a distance of 300 mm in lengths up to 1 m and are available in a choice of materials.

Leadscrews

Reliance leadscrew and nut assemblies provide a flexible, integrated solution for linear motion. Available in a wide choice of leadscrew sizes and nut styles, they are available in a range of materials and coatings with a choice of standard or custom machined interfaces.

A Vici Vision optical measurement system specifically for high accuracy lead screw measurement has recently been added into production.

Assembly

High precision clean components are assembled in Class 100 laminar flow cabinets. These assemblies are supplied to a diverse range of markets including scientific, medical, semiconductor and aerospace industries. A fully qualified ESD assembly area also allows handling of components sensitive to electro-static discharge.

Flexible shaft couplings

Coupling manufacture was introduced to Ireland in 1999 after a phase of development work. Recognising that the performance of a machine is only as good as the connections of its shafts, Reliance’s range of shaft couplings have been carefully designed and tested to provide trouble free operation over many millions of cycles.

The Reli-a-Flex™ range of couplings is an aluminium alloy, one piece configuration, which has been designed in-house to provide very smooth transmission of motion, high torsional stiffness, low bearing loads and long life.

The patented slot pattern was developed after many months of analysis and test. This provided the best balance between zero backlash, torsional stiffness and low bearing load, whilst attaining an operational life in excess of 50,000,000 cycles at rated load and 80% offset. With two sets of identical slots, the Reli-a-Flex™ coupling is a constant velocity by design, and handles angular, parallel and axial offset.

Ceramic grinding

Ireland has been responsible for Reliance’s ceramic grinding process since 2001, using jig boring machines in a controlled environment to machine ceramic components to an accuracy of 0.002 mm. The precision components are then assembled into a quadrupole mass filters.

These are used in the mass spectrometry industry, an area of technology in which Reliance is now regarded as a world leader.

Precision anti-backlash and standard gears

With over 50 years of experience in the design and manufacture of precision spur gears, Reliance has developed an extensive range to suit a wide variety of customer applications.

Reliance offers a wide selection of anti-backlash gears, spur gears, hubless gears and hardened gears with many hundreds of thousands of combinations of bore size, face width, material, module, and number of teeth.

Recently, Reliance have successfully concluded a phase of testing and development on a new CNC gear hobbing machine with automation for component loading and unloading. The addition of this machine further strengthens Reliance’s capabilities. This helps to increase productivity of standard gears with highly precise, highly accurate results.

It has also allowed the introduction of worm and worm wheel production.

Standard products

Ireland is home to Reliance’s Standard Products business and responsible for the supply of all catalogue products. These include products from essentials such as captive screws to complete sub-assemblies for rotary and linear motion and control.

Reliance also offer an integrated solutions assembly for more complex assembly or sub-systems comprised of standard, modified and bespoke elements.